Objectives of the Scandere project

This project aims to transform entire CRM value chains into more resource-efficient and circular systems for the EU’s interests. The major objective of the project is to create demonstrators with improved product designs, leaner remanufacturing, optimized recycling and adapted regulations in the context of a CRM-efficient PaaS business model from the sustainability perspective, through industry and academia collaboration across the EU. Also, the project is aiming for an even more improved, systemic design of the CRM efficient PaaS business models, improve the knowledge for product design, remanufacturing, and recycling including their interplays among them.

WP1 Developing PaaS offerings

WP1 consolidates the demonstration activities (on TRL6) in implementing design improvements in terms of CRM efficiency on three PaaS offerings already on the European markets based on scientific state of the art. For this purpose, a feasibility study in industry and interviews with practitioners will be performed. A desktop simulation with actors for EoL collection and reverse logistics in European countries with higher market potential for PaaS, based on insights gained by interviews with practitioners via industry associations involved in Scandere.

WP1 will identify opportunities and obstacles for PaaS reverse logistics. Another task for WP1 is to collect solutions to develop or improve PaaS offerings based on the scientific state of the art from the university partners. BSH will assess the applicability of scientific solutions for the PaaS offerings. BSH will develop and improve the two PaaS offerings (vacuum cleaners and washing machines) already on the European markets in terms of CRM efficiency that will be the core of demonstrators. LiU in close collaboration with a manufacturer improve a PaaS with robotic lawn mowers. Finally, WP1 will analyse learning outcomes (incl. opportunities and obstacles for PaaS), following principles of a multiple case study, as well as using results of WP2 and WP3.

WP2 Assessing European regulations for PaaS

WP2 aims to aims to show hindrances and supports in regulations in the EU member states regarding the concrete PaaS example offerings on the market (addressed in WP1).

Compliance & Risks are coordinating this WP by leveraging its C2P (Compliance 2 Product) database to help gain insights into what hindrances and supports in regulations in the EU member states exist that would impact a PaaS model. This review will take into account both in force and draft regulations and advise on the same.

Compliance & Risks will also undertake a review in the market with manufacturing entities (including Scandere partners) whom PaaS would impact and share insight / views on their appetite to gain inroads into this market.

WP3 Assessing the sustainability of PaaS offerings

WP3 aims to carry out the following activities, led by Linköping University in collaboration with all the other partners.

Performing lifecycle costing: This task evaluates the economic performance of the PaaS offerings using life cycle costing (LCC) from the standpoints of both providers and end users. The evaluation identifies the main contributors to costs, e.g., processes, cost categories, and the main choices that could influence the results.

Analysing social and environmental aspects: This task will qualitatively assess the social aspects with a social lifecycle assessment framework and SETAC guideline. The environmental aspects of the demonstrators are analysed with a focus on CRMs using a full lifecycle perspective. The analyses will give further understanding of the social and environmental impacts related to PaaS.

Generalizing learning outcomes from industrial cases in WP1: Based on the three demonstrators, this task aims to increase the knowledge of the impact of the design of PaaS on improved sustainability. The knowledge gained by analysing and synthesising the results in above tasks can be used to improve the PaaS offerings in WP1 and WP4. The aim is to make the derived knowledge and generalized insights applicable to other household EEE. This will boost the replication and transfer of the new CE business models and services across the EU.

WP4 Design research for PaaS

WP4 aims to develop a method (on TRL4) to align CRM-optimized PaaS design and the underlying PaaS business model. All the PaaS lifecycle phases are considered, and a desktop simulation platform to support the method usage will be proposed. This WP is led by Institut Polytechnique de Grenoble and performed in collaboration with all the other WPs.

First, based on an industrial practice survey, we will clearly formalize the scientific gaps as well as highlight the main needs for design methods in industrial practice.

Second, we will develop the design method, including formalization of knowledge, definition of user interface, development of the assisting tools, verification with PaaS cases, and improvement of the method and assisting tools.

Third, a desktop simulation platform will be proposed to apply the method on different cases in a practical, user-friendly manner. The design method will be applied in new PaaS projects. WP2’s outcome on regulation recommendations will be used as possible scenarios in design. The resulting designs will be tested as input to future remanufacturing and recycle in WP5 and WP6, respectively.

Lastly, we will generalize learning outcomes on design from industrial cases in WP1 and show that the developed method can be applied to PaaS from different industrial sectors.

WP5 Remanufacturing research for PaaS

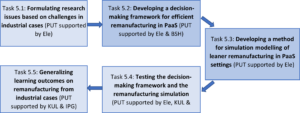

WP5 aims to develop the holistic guidelines through a decision-making framework for practitioners (on TRL6) and a simulation method (on TRL4) to move from current practices to a future desirable state of leaner remanufacturing in CRM-efficient PaaS business models.

Poznan University of Technology (PUT) will be coordinating this WP, and the Elektrorecycling S.A (Ele) will be the key industrial partner in this task. The scope of this WP is presented in Fig. 1.

In this WP the survey with Scandere partners and supporting organizations (including APPLiA Poland), will be conducted to map the current business practices. We will search answers for the questions:

Why currently recycling is dominant scenario for end-of-use electronic and electric equipment?

Which barriers the OEMs are facing to extend to use of remanufacturing and repair in the consumer’s markets?

Which factors (internal and external) might enable scaling up the application of remanufacturing in PaaS model for EEEs?

We will merge the findings from the industry survey and the literature review to find out the scientific gaps relevant for increasing the potential of remanufacturing in PaaS for electrical and electrical equipment (EEE) in business to consumer (B2C) markets.

The primary and secondary data (literature studies and industry reports), will be used to develop a decision-making (RD) framework to support the scaling up of remanufacturing in PaaS (especially in the B2C market). The proposed decision framework will enable synergies between the resource perspective (skills and technologies) and the process perspective (effective management of material flows to increase recovery). The framework will provide guidance for practitioners at the operational (operators), tactical (managers) and strategic (directors/owners of companies) levels to move toward TRL6. We will propose Key Performance Indicators (KPIs) for environmentally and economically viable remanufacturing of electrical and electronic equipment (SEE) in the PaaS model in consumer (B2C) markets.

The next step will be the development of a simulation modeling method using a high-level scripting language, which is similar to the language of industrial experts. We aim to create a simulation model that will allow testing various options for resource deployment and material flow in accordance with lean remanufacturing principles. A reference process library will be defined together with industrial partners. We will test through simulations experiments those interactions with WP4 (a new design approach) and WP6 (a new approach to recycling). The results of the tests will be generalized, by identifying the key elements necessary for their implementation in other companies. Educational materials will be developed for practitioners (enterprises) outside the consortium.

WP6 Recycling research for PaaS

WP6 aims to, in the context of PaaS, develop methods (on TRL4) to evaluate product designs for robotic recycling and investigate the feasibility of standardised fasteners and product architectures, and scalable recycling technologies to treat different models of product families that are likely to jointly return at end-of-(first)- life. This WP is led by KU Leuven and performed in collaboration with, among others, WPs 1, 4 and 5.

First, the product architecture will be investigated, as well as the design criteria that were considered in the early design phases. Then, the challenges and requirements will be assessed related to both destructive and non-destructive disassembly to increase the Critical Raw Material (CRM) recovery.

Second, novel assessment methods for the ease of robotic disassembly and dismantling will be developed, also incorporating various criteria that are highly relevant to robotic disassembly and are irrelevant for manual operations, e.g., the identification, clamping and positioning, uniform grasping and disconnecting.

Third, novel robotic disassembly technologies will be developed in accordance with novel fastener and product designs to reduce the production and dismantling costs and to increase the product robustness and aesthetic properties. Earlier experiences from the Re- and Demanufacturing lab at the KU Leuven in these fields will be used as a strong foundation for this development.

Lastly, the robustness and time efficiency of the robotic disassembly, dismantling and manipulation will be investigated, this for both the original products and products incorporating the developed novel prototype fasteners. These validation experiments will be performed utilizing various robotic setups in the re- and demanufacturing lab of the KU Leuven.